Cold Application of EcoAir® VpCI™-337

Background: TNT currently packages automobile parts in Italy and ships the parts to South America for assembly. During the winter season in Italy, the parts are cold, 0° to -10° C and with high levels of humidity. They would like to find water based rust preventative to apply to cold metal that gives corrosion protection.

Purpose: Determine if EcoAir® VpCI™-337 can be applied to cold steel parts and prevent corrosion during shipping.

Materials: Carbon Steel Plates

EcoAir® VpCI™-337

5-gallon bucket

Method: Environmental Chamber, (105° F, 95-100% Relative Humidity)

Procedure: The testing was designed to simulate the environment experienced during shipment from Italy to South America for the parts from TNT.

- Two carbon steel panels were cleaned and packaged in 5-gallon buckets.

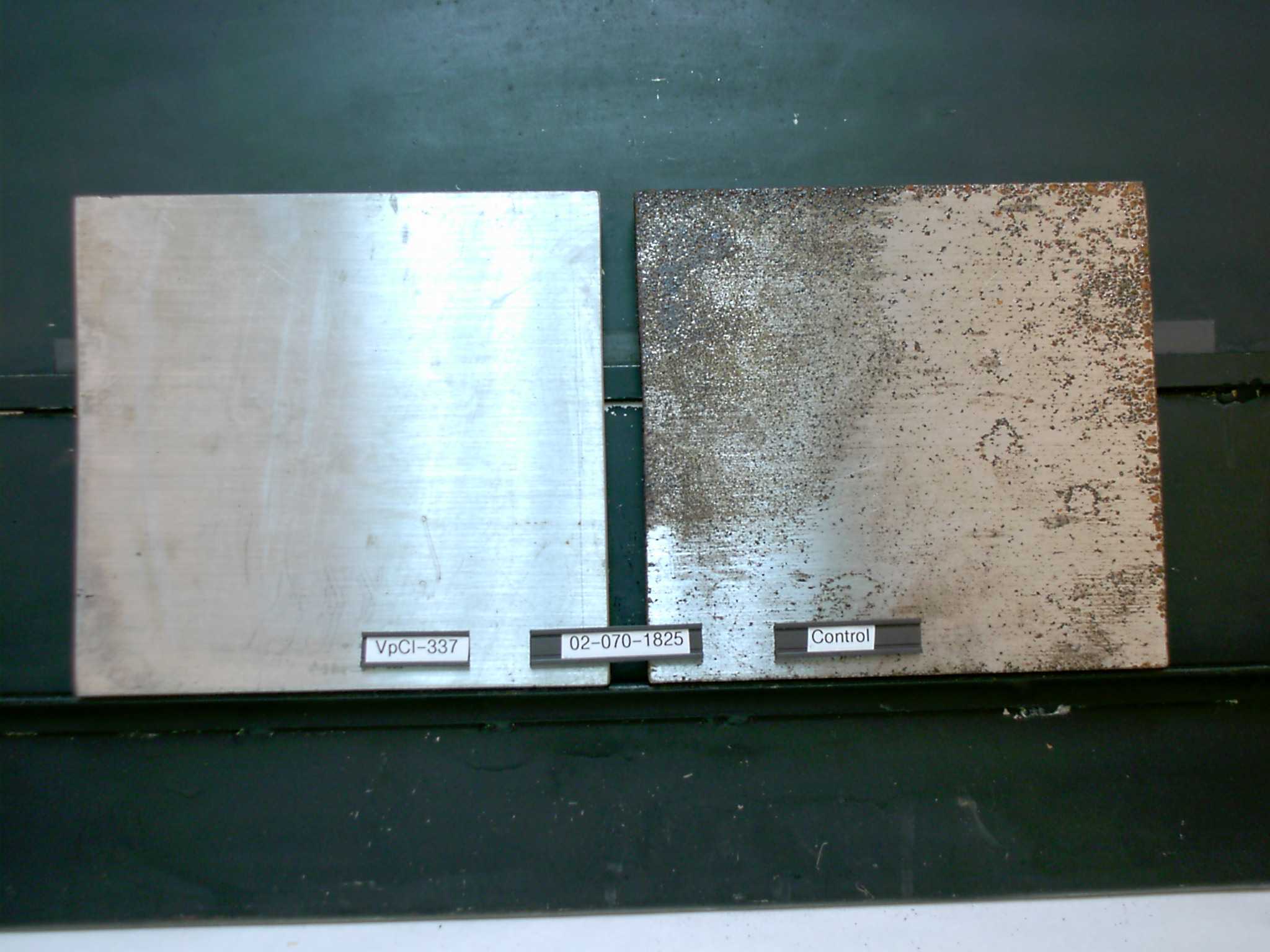

- The buckets were placed out of doors for 48 hours in temperatures ranging from -5° C to -12° C. One sample was left with no VpCI protection, the control, and the other bucket was fogged with EcoAir® VpCI™-337.

-

After 4 hours out of doors, the samples were placed in the environmental chamber, 105° F, 95-100% Relative Humidity. Periodically the samples were inspected, and after 12 days, the samples were removed from the environmental chamber. The samples were inspected, pictures were taken and a report was written.

Results: The following results were found:

|

Sample

|

Time to failure (days)

|

Percent corroded after 12 days

|

|

Control

|

2.5

|

76

|

|

EcoAir® VpCI™-337

|

Did not fail

|

0

|

Conclusion: EcoAir® VpCI™-337 protected the cold steel parts quite well. This testing suggests that EcoAir® VpCI™-337 applied to TNT’s parts cold should provide protection for shipments to South America.

Project #: 02-070-1825

Time Spent on Project: 5.5 hours

To: TNT, Italy

For: Dario Del Orto

From: Brian L. Wuertz

Date: 4-1-2002

cc: Boris Miksic

Art Albrecht

Margarita Kharshan

Cliff Cracauer

Vanessa Schultz

Bob Boyle