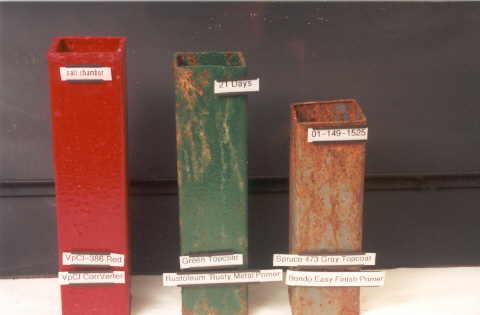

Comparison Testing of VpCI™ CorVerter®/VpCI™-386 vs. Conventional Coating Systems

Purpose: To compare VpCI™ CorVerter®/ VpCI™-386 vs. two conventional coatings systems in the salt spray chamber and environmental chamber.

Materials: VpCI™ CorVerter®

VpCI™-386 Red

Seymour Matchmaker Ivy Green

Premium RUST-OLEUM Rusty Metal Primer

Spruce 473 Ford Gray

Bondo Easy Finish Primer

2 large pieces of Structural Steel, cut into 3 pieces each

VpCI™-432

VpCI™-416

Method: ASTM B-117 (Salt Spray Chamber)

Environmental Chamber

Procedure: Two types of steel were received and were cut into 3 pieces each. A bench grinder was used to deburr and grind down the edges of the metal parts after being cut. They were washed and the coatings were removed and the surface was neutralized. One set of samples, angled, was left with some original coating on them to simulate poor surface preparation, which will be encountered in the real world. All of the old coating was removed from the tubing and all 6 samples were placed in the environmental chamber to corrode for 3 weeks, until sufficient corrosion had formed on the surfaces.

A wire brush was run over each surface once to remove loose corrosion. The samples were coated and designated as:

|

(Tubing) |

Primer |

Topcoat |

(Angled) |

Primer |

Topcoat |

|

Sample A1 |

VpCI™ CorVerter® |

VpCI™- 386 Red |

Sample A2 |

VpCI™ CorVerter® |

VpCI™- 386 Red |

|

Sample B1 |

Rustoleum Rusty Metal Primer |

Seymour Ivy Green |

Sample B2 |

Rustoleum Rusty Metal Primer |

Seymour Ivy Green |

|

Sample C1 |

Bondo Easy Finish Primer |

Spruce 473 Ford Grey |

Sample C2 |

Bondo Easy Finish Primer |

Spruce 473 Ford Grey |

VpCI™ CorVerter® and VpCI™-386 red were applied with a brush at the normal thickness specified on the PDS for these items. The rest of the coatings were applied from a spray can. Directions provided with each coating were followed and multiple coats were applied to give proper dry film thickness.

Results: After 2 days sample C1 and C2 failed the tests and corrosion was showing on both the parts. Around day 14 of the trial corrosion appeared sample B2 and on day 20 corrosion appeared on sample B1. Samples A1 and A2 never showed corrosion and are being placed back in the chambers and testing will continue until they fail. An addendum will be written when the testing is completed. After 21 days in the chambers, pictures were taken and the report was written.

Conclusion: VpCI™ CorVerter® and VpCI™-386 easily outperformed the Rustoleum/ Green and Bondo/Grey in both the Salt Spray Chamber and the Environmental Chamber. The VpCI™ CorVerter®/ VpCI™-386 has shown excellent protection and are expected to last many more hours in the chambers, a follow-up report will be written when testing concludes.

Project #: 01-149-1525

Estimated Cost of Project: $600.00

To: Boris Miksic, Cortec Corporation

From: Brian L. Wuertz

Date: 09-17-2001

cc: Anna Vignetti

Art Ahlbrecht

Cliff Cracauer

Vanessa Schultz

Christophe Chandler