Cortec® Introduces Game-Changing Corrosion Solution for Food Industry Boilers

December 31, 2025

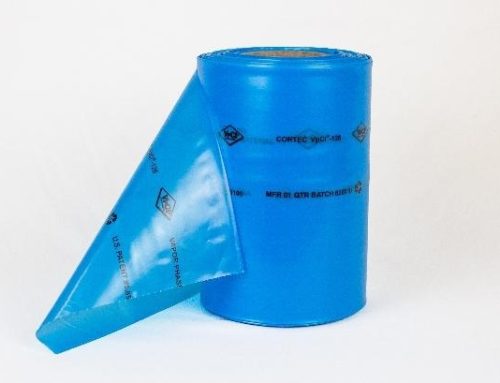

For decades, Cortec® corrosion solutions like the Boiler Lizard® have been a symbol of comprehensive and convenient protection for industrial boilers undergoing dry layup. Now, Cortec® is extending the same ease and effectiveness to the food processing industry with the introduction of the VpCI® Chameleon™, a game-changing boiler wet layup solution with NSF G6 certification (Reg. #172647) for use in food processing facilities.

Why Is VpCI® Chameleon™ Important in the Food Industry?

VpCI® Chameleon™ is an innovative corrosion inhibitor that simplifies and improves the wet layup process for boilers whose steam may come into contact with edible products in and around food processing areas. While corrosion protection is critical for all industrial boilers, it is more challenging in food processing facilities where chemicals could contaminate food or drink. Many food manufacturing processes require the production of steam that may come into direct contact with food. Some of these steam-producing boilers may need to remain offline occasionally due to fluctuations in the production schedule or to serve as backups to primary boilers. By using VpCI® Chameleon™ during these idle periods, food processing facilities can ensure that these assets stay corrosion-free and ready to restart at any moment, without endangering food safety.

How Does VpCI® Chameleon™ Stand Out from Other Methods of Wet Boiler Layup?

In nature, chameleons are known for their ability to blend in with their environment. They can also stand out in bold contrast to their surroundings, which is what the VpCI® Chameleon™ does when compared to traditional strategies for corrosion protection during boiler wet layup. The typical method for fighting corrosion in boilers during wet layup is to monitor the boiler water multiple times a week, adding sulfite and caustic as needed to maintain protection. This method is so time- and labor-intensive that it often gets neglected, leading to the corrosion problems it was meant to avoid. In contrast, VpCI® Chameleon™ does not require frequent monitoring or reapplication, saving significant time and labor costs and protecting boiler internals during the entire wet layup, independent of oxygen ingress levels. Furthermore, VpCI® Chameleon™ contains both vapor-phase and contact phase corrosion inhibitors, providing comprehensive protection below the water, above the water, and at the air/water interface. At the end of layup, boilers treated with VpCI® Chameleon™ do not have to be drained, allowing a faster return to service.

Why Does Corrosion Protection Matter?

Any idle boiler is at risk for corrosion that could lead to serious complications when the boiler is brought back online. These include “poisoning” of the water (high iron levels neutralize the effectiveness of other water treatment chemistries), clogging, thinning (even pitting) of boiler tubes, and leakage. Over time, these not only create temporary interruptions but also shorten the overall service life of the boiler system. Therefore, the use of a corrosion inhibitor during layup is an important investment with both short- and long-term benefits.

Start on the Path to Effective Boiler Layup

Corrosion protection during boiler layup is a critical part of industrial water treatment where Cortec® excels. With the development of VpCI® Chameleon™, Cortec® is now extending a legacy of convenient and comprehensive corrosion protection to the food industry. Contact Cortec® water treatment to get started on the path to easier and more effective boiler layup in food processing facilities with the VpCI® Chameleon™!

Keywords: Cortec, corrosion, corrosion solution, boiler corrosion, boiler layup, VpCI Chameleon, food industry corrosion, boiler wet layup procedure, boiler layup best practices, corrosion inhibitors

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

Related Articles

- FEATURED IN: Cortec Introduces Game-Changing Corrosion Solution for Food Industry Boilers Featured in Material Performance Magazine

- FEATURED IN: Cortec® Introduces Game-Changing Corrosion Solution for Food Industry Boilers Featured in Process Control Magazine

- FEATURED IN: Cortec® Launches Corrosion Solution for Food Industry Boilers Featured in CCR Magazine

- FEATURED IN: Cortec® Introduces Game-Changing Corrosion Solution for Food Industry Boilers Featured in Coatings Pro Magazine

- FEATURED IN: Comprehensive Corrosion Protection for Food-Industry Boilers Featured in Chemical Engineering Magazine

- FEATURED IN: VpCI Chameleon Corrosion Inhibitor Featured in Contractor Magazine

- FEATURED IN: Cortec Introduces Corrosion Solution for Food Industry Boilers Featured in Thermal Control Magazine

- FEATURED IN: Cortec® Introduces Game-Changing Corrosion Solution for Food Industry Boilers Featured in Asia Food Magazine

- FEATURED IN: Cortec Extends Boiler Protection Portfolio Featured in Food & Drink Technology Magazine

- FEATURED IN: Cortec Introduces Boiler Corrosion Inhibitor for Food Processing Featured in Food Engineering Magazine