Comparison of Fremont 5032 to Cortec Rust Preventatives

Comparison of Fremont 5032 to Cortec Rust Preventatives

Background: Precision Coatings currently utilizes Fremont 5032 as a Corrosion Inhibitor

Purpose: Compare the corrosion protection provided by Cortec’s VpCI®products to Fremont 5032.

Materials: Fremont 5032

VpCI-377

VpCI-378

EcoLine Cutting Fluid

Carbon Steel Bolts, provided by Precision Coatings

Method: Humidity Cabinet, Modified ASTM-D-1748

Procedure: The following procedure was followed:

- The bolts provided by Precision Coatings were coated as listed below:

- After coating the parts were allowed to dry for over 24 hours and then suspended in the humidity cabinet.

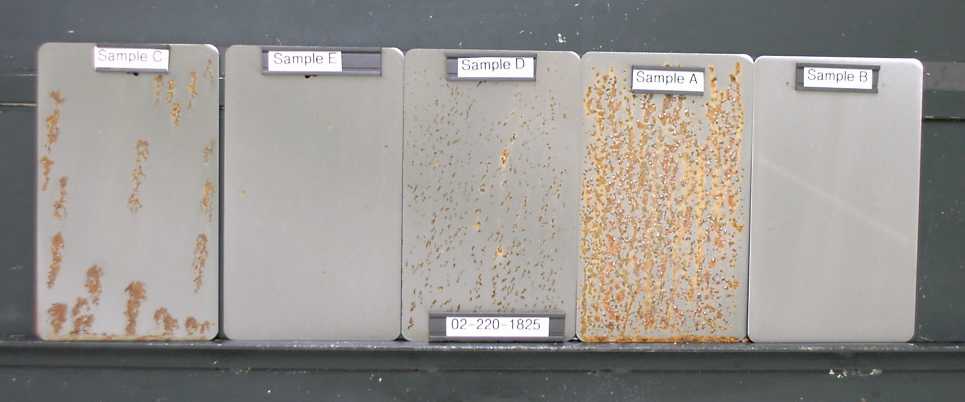

- Periodically the bolts were inspected, after 72 hours they were removed.

- Pictures were taken of the bolts and a report was written.

Results: The following results were found:

Results: The following results were found:

DNF = did not fail during testing

Conclusion: EcoLine Cutting Fluid, VpCI-377, and VpCI-378 provided excellent corrosion protection to the bolts provided by Precision Coatings.

Project #: 02-220-1825

Estimated Cost of Project: 4.5 hours

For: David Katz, Precision Coatings

From: Brian L. Wuertz

Date: 11-4-2002

cc: Boris Miksic

Anna Vignetti

Art Ahlbrecht

Cliff Cracauer

Bob Boyle

Ashish Gandhi

Vanessa Schultz