M 240 Prevents Corrosion Caused by Neopren Based Adhesive

M 240 Prevents Corrosion Caused by Neopren Based Adhesive

Background: Water based contact cement (Neopren based adhesive) causes the corrosion of carbon steel. Customer would like to find the additive to prevent this corrosion.

Purpose: To evaluate the performance of M 240 in neoprene based adhesive.

Method: Flash rust test

Half immersion test

Materials: Water based contact cement (Neoprene based adhesive - NBA), submitted by Franklin International.

M 240

Panels (Carbon Steel SAE 1010)

Methanol (Lab grade)

Procedure:

- Sample was prepared :

98%NBA+2% M 240 (% by weight)

- Compatibility of NBA with M 240 was evaluated. Sample was subjected to 14 days of heating at 40oC. The appearance of the product was visually evaluated.

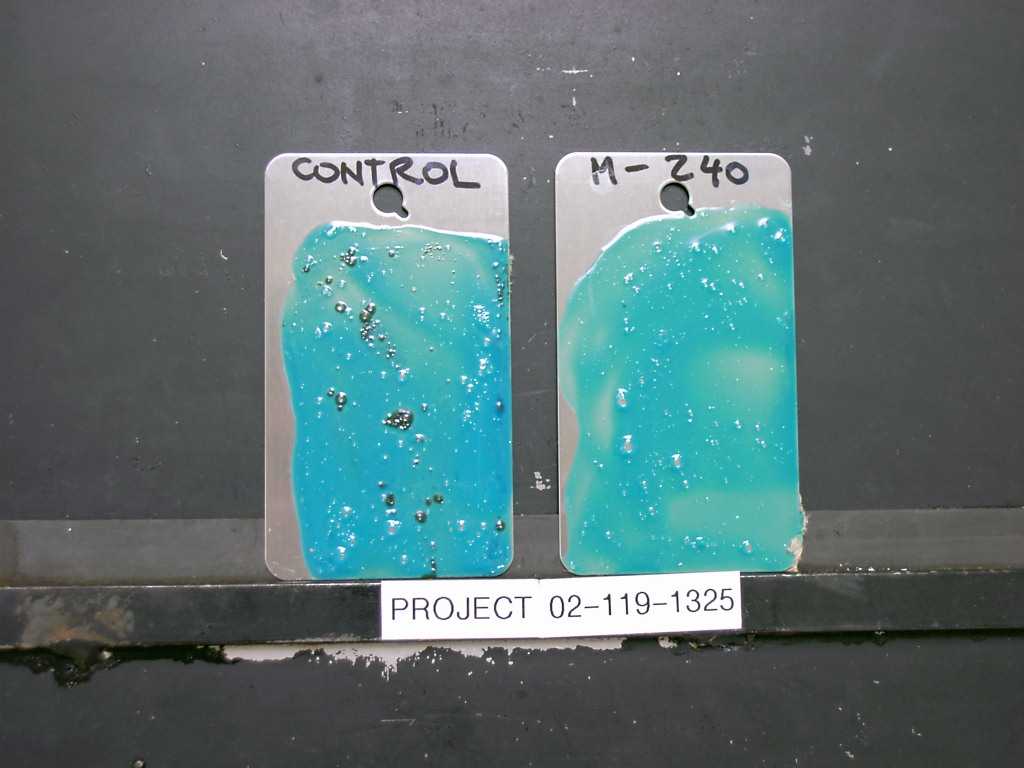

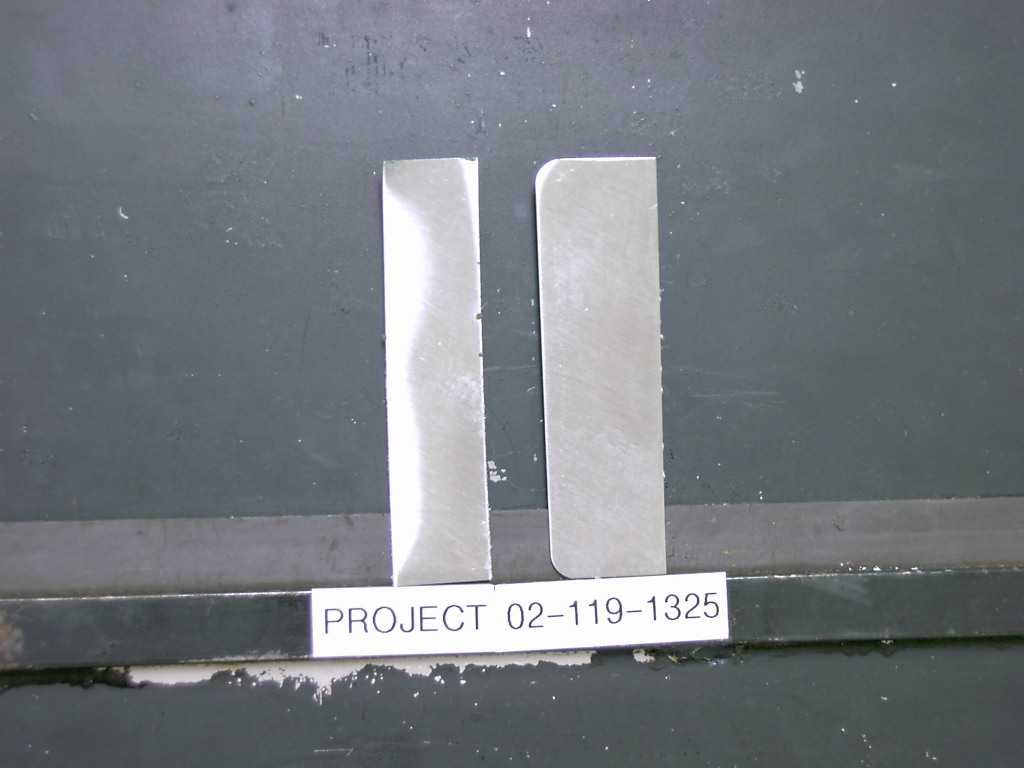

- Flash rust test was performed. Panels were cleaned with methanol, air dried, coated with products to test and air-dried at the room temperature for 24 hours. After that, panels were visually evaluated for the presence of corrosion.

- Half immersion test was performed according to the standard procedure for 96 hours at the room temperature.

Results:

.

|

Material |

Compatibility, changes in appearance |

Flash rust test, presence of corrosion |

Half immersion test, presence of corrosion |

| NBA |

No changes |

Corrosion |

Corrosion on the edges |

| 98%NBA +2%M 240 |

No changes |

No visible corrosion |

No visible corrosion |

(See attached photos)

Conclusion: M 240 prevents corrosion of carbon steel caused by Water Based Contact Cement (Neopren based adhesive), when added to it at concentration level of 2% by weight.

Project #02-119-1325

To: Lori Hilson, TH Hilson

For: Franklin International

From: Alla Furman/ Ivana Liposcak

Cc: Boris Miksic Margarita Kharshan

Anna Vignetti Ashish Gandhi

Art Ahlbrecht Vanessa Schultz