CASE HISTORY SPOTLIGHT: Case History #500: Steam Turbine and Boiler System Preservation

September 13, 2022

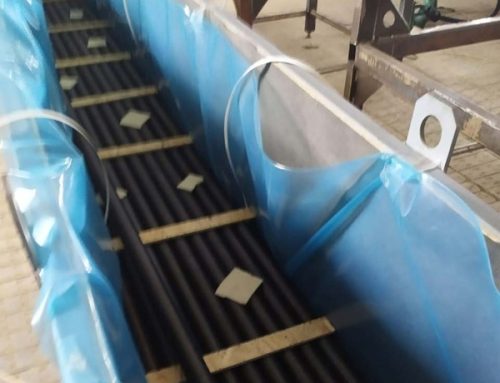

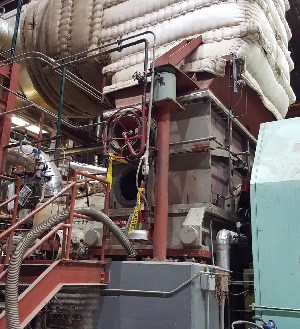

A power plant in Alaska needed to shut down and preserve its Unit 8 steam turbine, boiler system, and associated piping for three years. To do so, all access ports were first closed and sealed. One at the top and one at the bottom of the unit were opened to fog the void space with Cortec® VpCI®-337 corrosion inhibitors. A draft was created by installing a utility blower at the opposite end to help pull the fogging fluid through the extensive internal piping and vessel system. VpCI®-337 vapors can travel quite far on their own, so the blower was cycled on and off to make sure the vapors were not pulled through too quickly. When the proper dosage was reached, the openings were sealed and “VpCI® Protected” labels were added. The plant was very satisfied and excited about the application and confident that the steam turbine, boiler system, and associated pipeline would have an easy startup as a result.To read the full case history, please visit:https://www.corteccasehistories.com/?s2member_file_download=access-s2member-level1/ch500.pdfKeywords: steam turbine preservation, boiler preservation, power plant, VpCI, VpCI-337, VpCI protected, easy startup after layup, Cortec, corrosion inhibitors, boiler layupPDFclick here

A power plant in Alaska needed to shut down and preserve its Unit 8 steam turbine, boiler system, and associated piping for three years. To do so, all access ports were first closed and sealed. One at the top and one at the bottom of the unit were opened to fog the void space with Cortec® VpCI®-337 corrosion inhibitors. A draft was created by installing a utility blower at the opposite end to help pull the fogging fluid through the extensive internal piping and vessel system. VpCI®-337 vapors can travel quite far on their own, so the blower was cycled on and off to make sure the vapors were not pulled through too quickly. When the proper dosage was reached, the openings were sealed and “VpCI® Protected” labels were added. The plant was very satisfied and excited about the application and confident that the steam turbine, boiler system, and associated pipeline would have an easy startup as a result.To read the full case history, please visit:https://www.corteccasehistories.com/?s2member_file_download=access-s2member-level1/ch500.pdfKeywords: steam turbine preservation, boiler preservation, power plant, VpCI, VpCI-337, VpCI protected, easy startup after layup, Cortec, corrosion inhibitors, boiler layupPDFclick here