Cortec® Publishes Guide to Corrosion Remediation at Wind Farms

®®

The Stakes of Corrosion on Wind Turbines#

Steps to Mitigate Corrosion#

- Rust removal on various surfaces

- Protection of electric/electronic controls

- Coatings and MCI® for metal and concrete structural components, respectively

- Corrosion inhibitors for generators and motors

- Removable protection for nacelles and blades (e.g., while awaiting commissioning)

Time to Hit the Brakes#

®reach out to us with specific questions.®®

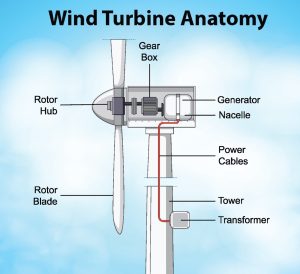

Wind Turbine:#

- Gearbox (various carbon steels)

- High speed and low speed shaft (various carbon steels)

- Brake (various carbon steels and non-metallic pads)

- Generator and motors (carbon steel, copper, stainless steel, insulation)

- Drive mechanisms (various carbon steels)

- Electric/electronic controls (carbon steel, copper, stainless steel, insulation)

- Tower (pre-stressed concrete or steel)

- Base/foundation (steel-reinforced concrete)

- Nacelle

- Blades

Gearbox:#

- M-535 as an additive to run in oil or as a fogging application (1 oz/ft3 [1 L/m3]).

- NOTE: Not to be used in operating oil unless detailed compatibility testing is completed.

- VpCI®-391 or EcoShield® VpCI®-386 clear for all exposed machined surfaces.

- Coating of exterior surfaces (options):

- VpCI®-422 and VpCI®-414 for removing any internal rust.

- VpCI®-423 or VpCI®-422 with VpCI®-414 to remove any external rust.

High Speed and Low Speed Shaft:#

- VpCI®-391 or EcoShield® VpCI®-386 clear for all exposed machined surfaces.

- VpCI®-423 or VpCI®-422 with VpCI®-414 to remove any external rust.

Brake:#

®

- VpCI®-391 or EcoShield® VpCI®-386 clear for all exposed machined surfaces.

- VpCI®-423 or VpCI®-422 with VpCI®-414 to remove any external rust.

Generators and Motors:#

- VpCI®-239 for fogging into the generator and motor core (ensure the generator and motor are not energized).

- VpCI®-391 or EcoShield® VpCI®-386 clear for all exposed machined surfaces.

- VpCI®-423 or VpCI®-422 with VpCI®-414 to remove any external rust.

- VpCI®-101 Device placed in junction boxes.

- Coating of exterior surfaces (options):

- Prime with VpCI®-395 and topcoat with EcoShield® VpCI®-386 (color match).

- Prime with VpCI®-396 and topcoat with VpCI®-384 (color match).

Drive Mechanism:#

- VpCI®-391 or VpCI®-386 clear for all exposed machined surfaces.

- VpCI®-423 or VpCI®-422 with VpCI®-414 to remove any external rust.

®

Electric/Electronic Controls:#

- Spray all internal surfaces with VpCI®-239.

- Install appropriately sized emitter:

Tower (Steel):#

- Option to (a) remove existing rust with VpCI®-423 and VpCI®-414 or (b) power wash to remove surface contaminants and loose debris, and coat with CorrVerter® Rust Converter Primer.

- Coat interior or exterior surfaces (options):

- Prime with VpCI®-395 and topcoat with EcoShield® VpCI®-386 (color match).

- Prime with VpCI®-396 and topcoat with VpCI®-384 (color match).

Tower (Pre-Stressed Concrete):#

- Power wash to remove surface contaminants and loose debris.

- Apply Migrating Corrosion Inhibitors such as MCI®-2020/2020 V/O to cleaned surface.

- Apply Cortec® MCI®-2018 to treated surface.

- Contact Cortec® Migrating Corrosion Inhibitor™ specialists for proper selection and application technique.

- NOTE: Migrating Corrosion Inhibitors such as MCI®-2005/2005 NS can be added to the concrete during the construction phase to protect the steel rebar reinforcement to extend tower life.

Base/Foundation:#

- Power wash to remove surface contaminants and loose debris.

- Apply MCI®-2020 to cleaned surface.

- Apply MCI®-2018 to treated surface.

- Contact Cortec® Migrating Corrosion Inhibitor™ specialists for proper selection and application technique.

®

Nacelle:#

- Option to (a) remove existing rust with VpCI®-423 and VpCI®-414 or (b) power wash to remove surface contaminants and loose debris, and coat with CorrVerter® Rust Converter Primer.

- Paint interior or exterior surfaces (options):

- Prime with VpCI®-395 and topcoat with EcoShield® VpCI®-386 (color match).

- Prime with VpCI®-396 and topcoat with VpCI®-384 (color match).

Blades (Metallic):#

- Clean with VpCI®-414.

- Coat with VpCI®-391.

- Shrink wrap with either MilCorr® VpCI® Shrink Film or VpCI®-126 HP UV Shrink Film.

Blades (Non-Metallic):#

- Clean with VpCI®-414.

- Coat with VpCI®-391.

- Shrink wrap with either MilCorr® VpCI® Shrink Film or VpCI®-126 HP UV Shrink Film.

Keywords: guide to corrosion remediation at wind farms, Cortec, corrosion remediation, wind industry, corrosion solutions, wind turbine corrosion, rust prevention on wind turbines, generator corrosion, investing in wind turbines, protection on wind turbine bladesPDFclick here®