Corrosion Mitigation for Flatbed Freight: Logistics Solutions That Work

November 25, 2025

How would you get a giant chiller or metal ring from point A to point B? A good answer is “by flatbed truck.” An even better answer is “by flatbed truck with a reliable corrosion protection strategy in place.” For manufacturers of large or awkward items who prefer the second option, Cortec® is here to get them started on the road to rust-free shipment with the following tips for flatbed freight.

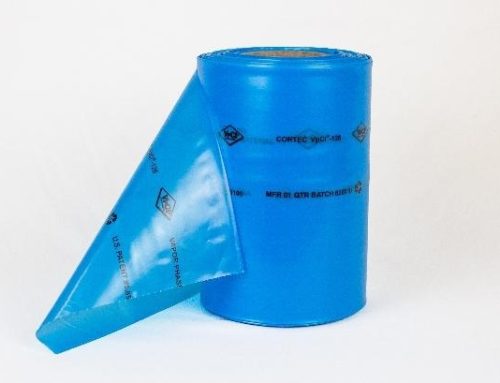

Tip One: Replace Tarps with VpCI® Shrink Film

The riskiest way to ship metal goods is by strapping them to an open truck bed without any cover, exposed to wind, rain, snow, sea spray, and tropical climates. This is especially true for uncoated steel rebar, piping, or metal beams. While throwing a tarp over the top of the shipment offers some physical protection, it doesn’t account for the potential moisture and condensation that could still make its way under the tarpaulin cover. To take protection to the next level, manufacturers should choose a corrosion inhibiting film such as VpCI®-126 HP UV Shrink Film or (for the harshest conditions) MilCorr® VpCI® Shrink Film. When shrink wrapped around metal goods and equipment, these films not only create a physical barrier to the elements but also contain Vapor phase Corrosion Inhibitors that actively fight corrosion in case of moisture and salt ingress or condensation. One chiller manufacturer who adopted this method found that complaints about receiving corroded goods disappeared. The manufacturer later added fogging of internal piping with the Boiler Dragon™ to their shipping prep process for enhanced corrosion protection.*

Tip Two: Use a Clear Removable Coating When Film Is Not Ideal

While shipping large, awkward items in VpCI® film is an excellent method of corrosion protection, some situations pair better with a removable coating. For example, fire trucks have been effectively prepped for transport by spraying VpCI®-391 removable coating right over the finish of the truck. Since the coating is inconspicuous, the end users can decide whether or not to remove the coating. Steel beams or rebar shipped on the back of an open truck can be protected with a similar removable coating such as MCI® CorShield® to keep these building materials in like-new condition until installation.

Tip Three: Think About the Bigger Picture

In some cases, manufacturers need to take a more comprehensive approach based on the complexity of the goods and the length of the journey. For example, it took one giant pump one month to travel more than 5,000 miles (8,047 km) by land. Preparation included hydrotesting with VpCI®-649 BD, fogging pump internals with VpCI®, adding M-531 to the oil system, and spraying a variety of protective coatings on unpainted metals and other surfaces in need of extra protection. VpCI®-105 Emitters went inside electrical boxes, and the entire package was finished by wrapping the pump in MilCorr® VpCI® Shrink Film for external protection.**

Tip Four: Get Expert Assistance for a Custom Corrosion Solution

It is difficult enough to get large, awkward equipment from one place to another without having to worry about corrosion protection. Yet, the second part can be relatively easy, thanks to VpCI® solutions that make an excellent companion to flatbed truck shipments. If you need help developing a corrosion solution tailored to the coils, chillers, or heavy equipment you need to ship cross-country, contact Cortec® for expert assistance on safeguarding your flatbed freight.

* Cortec® Case History 861 (login required): https://www.corteccasehistories.com/

** Cortec® Case History 700 (login required): https://www.corteccasehistories.com/

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.