Doing the Math on Aerospace Packaging Efficiency: Two Bags or One?

September 30, 2025

Why use two bags when you can use one? Too often, we take more steps than necessary to accomplish a task. It sometimes demands an outside perspective to gently point out a more efficient solution that makes life easier—which is what Cortec® distributor Lake Engineering Solutions did for an important aerospace company that streamlined its packaging process down to one bag instead of two.

Packaging Protection for Precision Machined Parts

The client demanded strict quality control to ensure the integrity of precision machined metal parts used in the internal build of aircraft wings and doors. That meant both corrosion and mechanical protection were needed during the unpredictable shipping and handling stage. Lake Engineering Solutions had already met the first need with VpCI®-126 Top-Seal bags that protected the components via a molecular layer of Vapor phase Corrosion Inhibitors which left the parts dry and ready to install. The second layer of protection came from standard bubble bags that provided cushioning on the way to the assembly plant.

A Streamlined Solution for Packaging Sensitive Aerospace Components

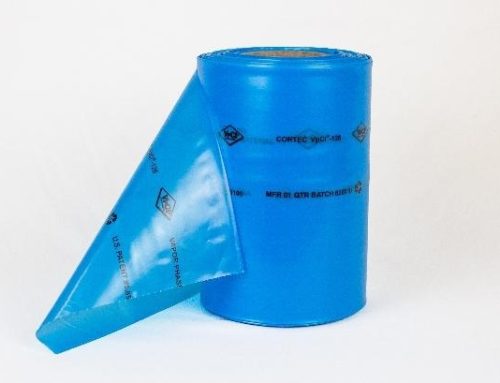

One day when visiting the client, Lake Engineering noticed the double-bagging process and suggested a customized solution: replace two bags with one Cortec® Cor-Pak® VpCI®-126 Bubble Bag (also known as VpCI®-126 Bubble Bag with sealable lips) that provided dual cushioning and corrosion protection. The manufacturer adopted the solution and immediately began saving time by eliminating an extra packaging step while achieving a high level of protection up to company specifications.

Quality Control and Tracking of Aircraft Components

To further reinforce the integrity of their packaging process, the company introduced a comprehensive tracking system. This included a strict non-reuse policy, date monitoring, and colour-coded stickers for easy identification and traceability. These measures guaranteed consistent, robust protection and aligned with the company's commitment to quality and operational excellence in the aerospace sector.

Save Time, Simplify, Succeed!

Similar measures can be taken in any industry that requires multifunctional packaging protection such as corrosion + cushioning protection or corrosion + ESD protection. Contact Cortec® or your local distributor today to discover a wide variety of corrosion inhibiting solutions to streamline your packaging process and enhance your quality assurance!

Keywords: aerospace packaging, packaging efficiency, aerospace efficiency, packaging aircraft parts, aircraft packaging, packing aircraft parts, corrosion on aircraft parts, rust prevention, Cortec, VpCI

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

Related Articles

- FEATURED IN: One Bag or Two: Doing the Math on Aerospace Packaging Efficiency Featured in Design World Magazine

- FEATURED IN: Doing the Math on Aerospace Packaging Efficiency: Two Bags or One Featured in Coatings Pro Magazine

- FEATURED IN: Streamlining Aerospace Packaging with Cortec® Innovation Featured in IPCM Magazine

- FEATURED IN: Packaging Efficiency in Aerospace with Cortec Featured in MSN Magazine

- FEATURED IN: Streamline Packaging Solutions Featured in Logistics Business Magazine

- FEATURED IN: Packaging Efficiency in Aerospace with Cortec Featured in AZO Materials Magazine

- FEATURED IN: Doing the Math on Aerospace Packaging Efficiency: Two Bags or One Featured in Electronics Era Magazine

- FEATURED IN: Doing the Math on Aerospace Packaging Efficiency: Two Bags or One Featured in SP News