Don’t Let Static Distract You From Electronics Corrosion Protection

November 4, 2025

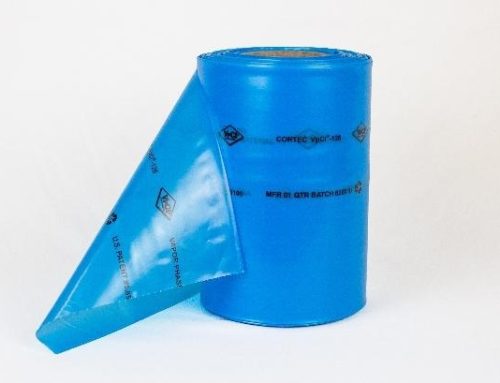

Static is distracting—whether it’s on the phone or the radio—and it makes communication difficult. For electronics, it is also physically damaging—so much that it inspires entire conferences focused on preventing electrostatic discharge (ESD) damage during manufacturing, shipping, and beyond. Yet with all the emphasis on ESD protection, it is important not to be distracted from other electronics quality concerns, such as corrosion protection—especially when EcoSonic® VpCI®-125 HP Permanent ESD Film & Bags from Cortec® Corporation address both issues in one streamlined packaging solution.

Benefits of Permanent ESD

EcoSonic® VpCI®-125 HP Permanent ESD Film & Bags are a great place to start for any ESD specialist or packaging engineer who wants long-term ESD protection. These bags rely on a permanent ESD additive to reduce or eliminate the static that could build up and cause silent damage simply when moving a part from one place to another or slipping an electronic sub-assembly inside a bag. Permanent ESD offers a much more reliable, long-lasting form of ESD protection than traditional “pink poly” and is a great choice for distributors that need ESD protection to last several years while their electronics sit on a shelf waiting to be ordered.

Corrosion Protection and Quality Control

Cortec®® makes it easy for electronics manufacturers and distributors to tackle another quality issue—corrosion—at the same time. The multiple metal types used in electronics face corrosion risks during shipping and storage when uncontrollable environmental conditions may prompt condensation and corrosion and lead to premature electronic failures. With high quality control (QC) demands, even questionable discoloration of metal may cause a part to be rejected, making corrosion protection worthwhile. EcoSonic® VpCI®-125 HP Permanent ESD Bags address this issue by adding Cortec® VpCI® to the mix, conditioning the package with Vapor phase Corrosion Inhibitors that form a protective molecular layer on multi-metal surfaces and simply float away when the item is removed from the bag.

Streamline Your Electronics Packaging Process

Often, multiple goals require multiple packaging materials. For example, one electronics distributor used to place desiccant into ESD moisture barrier bags to protect against both static and moisture.* After encountering the idea of ESD + corrosion protection, they decided to try replacing the two materials with one EcoSonic® VpCI®- 125 HP Permanent ESD Bag. The packaging first underwent quality testing to ensure it met appropriate electronics packaging requirements. Later, it underwent humidity testing to compare the new bags against the previous packaging system of moisture barrier bags plus desiccant. The distributor was satisfied with the results, has been using EcoSonic® VpCI®-125 HP Permanent ESD Bags for several years, and has expressed interest in adopting other Cortec® dual ESD + VpCI® protective packaging options. By eliminating the desiccant, the distributor has streamlined their packaging process to achieve dual ESD and corrosion protection in one bag.

Tackle Two Quality Issues with One Bag

ESD protection is important, but it’s not the only part of the picture. By opting for EcoSonic® VpCI®-125 HP Permanent ESD Bags, electronics manufacturers and distributors can get baseline static dissipation while expanding to corrosion protection and potentially eliminating extra packaging material like desiccant. Contact Cortec® to learn more about achieving quality ESD and corrosion protection with this two-in-one packaging material.

* Cortec® Case History #812: https://www.corteccasehistories.com/

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

Related Articles

- FEATURED IN: Don’t Let Static Distract You From Electronics Corrosion Protection Featured in Packaging Connections Magazine

- FEATURED IN: Don’t Let Static Distract You From Electronics Corrosion Protection Featured in Electrical Trade Magazine

- FEATURED IN: Don’t Let Static Distract You From Electronics Corrosion Protection Featured in MEM Infrastructure Magazine

- FEATURED IN: Streamlined packaging protects electronics from ESD and corrosion Featured in Electro Pages Magazine

- FEATURED IN: Cortec Ecosonic Film Combines ESD and Corrosion Protection for Electronics Featured in Electronics Magazine

- FEATURED IN: Cortec’s EcoSonic Film Combines ESD and Corrosion Protection Featured in Construction World Magazine

- FEATURED IN: Don’t Let Static Distract You From Electronics Corrosion Protection Featured in SMT Magazine

- FEATURED IN: Don’t Let Static Distract You From Electronics Corrosion Protection Featured in Electronics Era Magazine