EcoCortec® Pioneers the Future of Sustainable Packaging for the Circular Economy

November 19, 2025

The global landscape is moving decisively towards a model where performance and environmental responsibility are inseparable. While effective material protection remains essential, industry leaders now recognize that true value lies in solutions that embrace the entire product life cycle. It is no longer enough to simply protect goods from corrosion and damage; packaging must also align with the highest sustainability standards and circular economy principles. This commitment is amplified by regulatory drivers like the forthcoming EU PPWR Regulation, which champions materials that simplify end-of-life management.

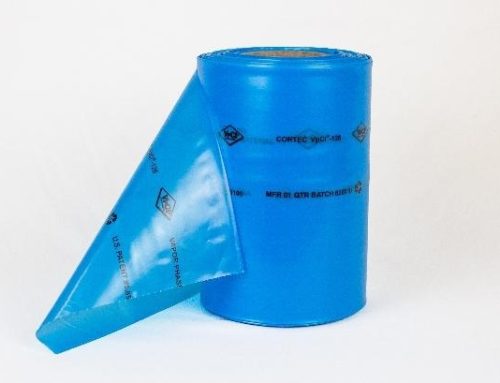

As the European counterpart of Cortec® Corporation, EcoCortec® (located in Croatia) is dedicated to developing materials that support this transition to biodegradable and compostable solutions and advanced PCR packaging. This commitment to innovation enables manufacturers to achieve effective corrosion protection while using environmentally responsible solutions. EcoCortec’s “green” portfolio of films and bags is designed not just for corrosion protection but engineered to safely return materials to the earth at their end-of-life, securing a cleaner and more responsible future for industry. Through continuous investment in R&D, EcoCortec® has pioneered a portfolio of film technologies designed to contribute to the circular economy, ensuring their clients receive packaging without the waste burden.

EcoWorks® films and bags can be used for checkout bags, lawn and leaf bags, organic waste diversion, and other industrial and commercial uses. When placed in a typical commercial composting environment, they fully biodegrade within months. Eco Works® 100 contains 100% USDA certified biobased content and is certified industrially compostable by TÜV Austria (#TA8012509046).

Eco-Corr Film® ESD biodegradable high performance anti-static, corrosion inhibiting film and bags from EcoCortec® are made for use in the protection of static sensitive multi-metal items such as electronics. They contain permanent anti-static properties to immediately reduce or eliminate static buildup as long as the films or bags are in use, independent of the presence of humidity.

EcoFilm® is a certified commercially compostable film designed to replace traditional polyethylene films. The film is shelf and curb stable, meaning it retains its integrity until properly disposed of in commercial composting facilities, making it an ideal choice for large-scale organic waste programs.

EcoShrink™ designed for use in standard heat-shrinking applications and is certified to a major standard of compostability. It breaks down into non-toxic substances H2O, CO2, and biomass, leaving no microplastic residue. After use, it can be disposed of in a commercial composting environment (check locally before disposal) to reduce the amount of plastic packaging that normally ends up in a landfill.

Eco Wrap® is a specialty industrially compostable wrapping film made with certified compostable resin plus a tackifier additive. It is designed to run on existing stretch film equipment by simply adjusting the tension setting. Eco Wrap® is commercially certified compostable to help avoid tariffs and fines in areas where polyethylene is restricted.

EcoBio™ Barrier Paper is new premium recyclable, repulpable, biodegradable barrier paper aimed at a variety of short-term packaging applications where moisture or grease is a concern. It starts the product life cycle as 100% recycled paper stock coated with a biobased (90-100% renewable organic carbon per ASTM D6866) and biodegradable (per OECD 301) barrier coating. It has no intentionally added plastics (or PFAS or fluorochemicals) to hinder recycling or biodegradation. EcoBio™ Barrier Paper can be recycled through normal paper recycling streams instead of ending up in the landfill. However, this paper goes a step further with its biodegradable, biobased coating that has the potential to open even more sustainable end of life options depending on local regulations. Most importantly, EcoBio™ Barrier Paper tackles moisture and grease resistance without the risk of plastic or foil pollution.

“The move toward genuinely sustainable packaging is not just an economic and environmental imperative. Products like EcoBio™ Barrier Paper are vital because they allow industries to maintain product integrity and safety without sacrificing the planet. Its features make it incredibly appealing as a direct replacement for conventional plastic packaging, especially when we consider its potential to carry specialized features like superior barrier, anticorrosion, and ESD properties," says Boris Miksic, CEO of Cortec® Corporation. "Our . . . sustainable VCI/VpCI® packaging line delivers uncompromised corrosion protection while guaranteeing a plastic-free end-of-life, whether through recycling, compostability, or biodegradation," he concludes.

The complete EcoCortec packaging assortment is detailed in our company brochures, which you can explore here: https://ecocortec.hr/eng/brochures

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

Related Articles

- FEATURED IN: EcoCortec® Pioneers the Future of Sustainable VCI Packaging for the Circular Economy Featured in Industry Wiz Magazine

- FEATURED IN: EcoCortec Touts Broad Portfolio of Sustainable VCI Packaging Featured in Packaging Industry News

- FEATURED IN: EcoCortec® Pioneers the Future of Sustainable VCI Packaging for the Circular Economy Featured in Packaging Connection Magazine

- FEATURED IN: EcoCortec Supports Biodegradable and Compostable Packaging Featured in Adsale Packaging Magazine

- FEATURED IN: EcoCortec® Leads the Way in Sustainable VCI Packaging for a Circular Economy Featured in Food & Beverage Magazine

- FEATURED IN: EcoCortec Touts Broad Portfolio of Sustainable VCI Packaging Featured in Packaging Strategies Magazine

- FEATURED IN: EcoCortec® Leads Sustainable VCI Packaging Innovation for the Circular Economy Featured in Urja Daily Magazine

- FEATURED IN: EcoCortec® Leads Sustainable VCI Packaging for Circular Economy Featured in Poly Mart Magazine

- FEATURED IN: EcoCortec Sets Sustainability Benchmark with Compostable Corrosion-Protection Packaging Featured in Towards Packaging Magazine

- FEATURED IN: EcoCortec develops compostable VCI packaging ahead of EU waste rules Featured in MSN Magazine

- FEATURED IN: EcoCortec launches compostable corrosion-inhibiting packaging for EU market Featured in Sustainable Packaging Magazine

- FEATURED IN: EcoCortec develops compostable VCI packaging ahead of EU waste rules Featured in Yahoo News

- FEATURED IN: EcoCortec develops compostable VCI packaging ahead of EU waste rules Featured in Packaging Gateway Magazine