PRESS RELEASE: How to Protect New MCCs from Corrosion During Shipping and Storage

April 13, 2023

MCCs (motor control centers) play a critical industrial role as the control hub for electrical motors in a facility. They are especially common on offshore platforms where motors are used to operate BOPs, mud pumps, boiler room equipment, and much more. As with any component that is fabricated offsite and shipped through unpredictable environments, MCCs need special protection against corrosion before they are ever installed or operating. An easy solution is the use of Cortec® VpCI® Technology to reduce MCC corrosion damage even in uncontrolled climates.

MCC Corrosion Risk Scenario

The level of protection needed depends on where the MCCs are made, how far they are shipped, and where they will be stored. An extreme scenario is that of oil and gas production modules being assembled in Southeast Asia and shipped to remote areas on another continent. In the hot coastal environment where their journey begins, humidity is high and salt-spray laden air is abundant, presenting dual corrosion threats to the new equipment. Added to this risk is the fact that new MCCs may be placed on an open deck of the growing module, exposed to the atmosphere until other components are built around it. From there, the MCCs may need to cross multiple oceans and travel through many latitudes, with serious condensation forming inside the MCCs as the weather changes from hot to cold. Furthermore, unpredictable shipping delays may leave the MCCs in extended storage at a coastal port before the equipment finishes its journey. All this time, sensitive equipment that would typically be climate controlled is at the mercy of harsh environmental conditions, vulnerable to corrosion damage before it is ever commissioned.

Enhanced Corrosion Protection for MCCs

One of the most common methods for MCC protection apart from climate control is the use of desiccant to absorb any moisture that makes its way into the compartment. This basic corrosion inhibiting strategy can be greatly enhanced by adding Cortec® corrosion inhibitors in a variety of forms. Contact corrosion inhibitors protect metal surfaces that they are directly applied to by way of a thin coating or plastic packaging material. Vapor phase Corrosion Inhibitors go a step beyond by diffusing through the airspace of an enclosure and adsorbing on metal surfaces as a molecular protective layer that discourages interaction with corrosive elements such as oxygen, chlorides, and moisture. A special advantage is that Vapor phase Corrosion Inhibitors protect difficult to reach areas without the hassle or concern of direct application.

How to Apply Corrosion Protection to MCCs

The following method can be used to apply corrosion protection to MCCs. Suggested protective materials should be chosen based on the actual size and shipping/storage conditions of the MCC. Once the MCCs are hooked up to electricity and commissioned, they should not be opened because of high voltage concerns. However, at early stages of manufacturing and assembly, this may not be a concern and the MCCs should be treated internally when access is an option.

- Electrical contacts should be sprayed with ElectriCorr™ VpCI®-239, which dries into a very thin film that protects against aggressive conditions.

- VpCI® emitting devices can also be placed inside MCC components for vapor-phase protection throughout the enclosures according to the space’s volume (VpCI®-101 Devices for 1 ft³ [28 L], VpCI®-105 for 5 ft³ [0.14 m³], and VpCI®-111 for 11 ft³ [0.31 m³]). MCCs the size of an entire room can be protected by adding one VpCI®-308 Pouch per 35 ft³ (1 m³) of internal space.

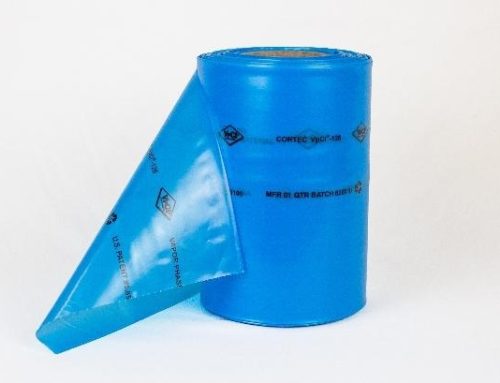

- MCCs in need of external protection can be wrapped in VpCI®-126 HP UV Shrink Film, which contains contact and vapor-phase inhibitors along with special UV properties for outdoor durability. (If desired, a VpCI®-308 Pouch can be added in between the film and the MCC sides for additional external protection.)

Get Started on Your MCC Preservation Plan

MCCs are critical assets with high value. Those responsible for making sure they arrive onsite in good condition must be careful to protect against the unforeseen corrosion risks MCCs will encounter along the journey. Adding the power of Cortec® VpCI® Technology goes a long way toward fighting the corrosive elements to which MCCs will be exposed, helping to save valuable equipment from unnecessary damage and repair. Contact Cortec® for further assistance in putting together a preservation plan for transit and storage of MCCs: https://www.cortecvci.com/contact-us/

Keywords: MCC, motor control centers, how to protect MCCs from corrosion, corrosion during shipping and storage, Cortec, VpCI, corrosion protection, corrosion risk scenario, MCC preservation plan, corrosion inhibitors

Need a High-Resolution Photo? Visit: www.cortecadvertising.com

For a PDF version please click here.