Not a Myth: Easy Power Plant Rust Prevention with Boiler Dragon™

June 19, 2024

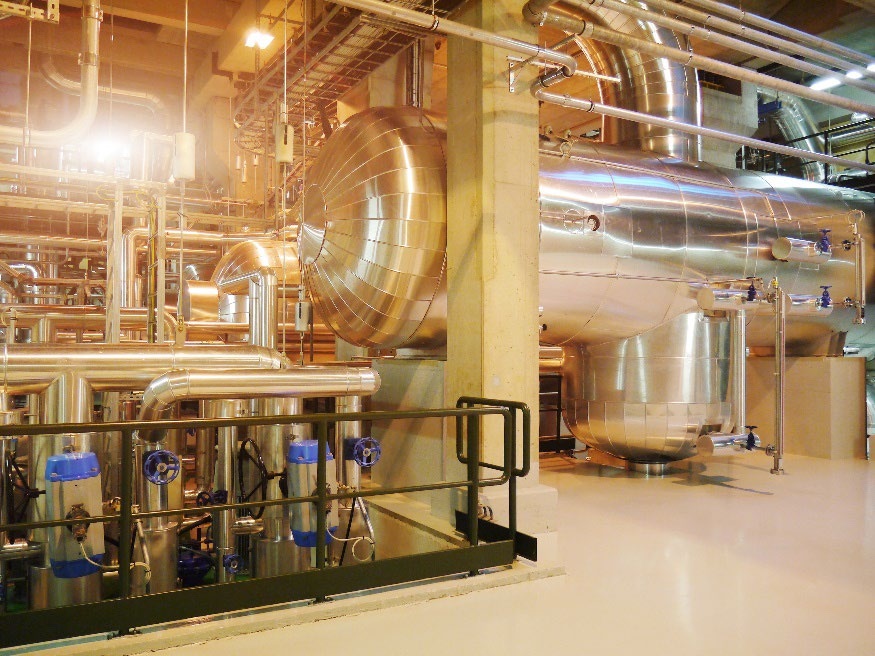

What if every time you shut down your boiler for maintenance and started it up again, it threw so much rust into the air that the neighbors complained? What if your boiler water’s iron levels were routinely high after startup, and your boiler tubes needed early replacement? What if you tried to prevent these problems by using dehumidification or nitrogen blanketing, but the systems failed halfway through layup? These are real concerns for power plants that rely on steam production from boilers and HRSGs to generate power. While the idea of using corrosion inhibitors to “fog and forget” a laid up system may seem too good to be true, Cortec® posits that such easy protection is not a myth, thanks to the Boiler Dragon™.

The VpCI®-Breathing Dragon

The Boiler Dragon™ is a waterborne fogging fluid that contains Vapor phase Corrosion Inhibitors (VpCI®). It can be fogged into equipment voids (both water side and fire side) at a rate of 0.7-1.0 fluid ounces per cubic foot (0.7- 1.0 L/m³), or one gallon per 1,000 gallons of boiler volume (1 L/1 m³). This makes it economical and adaptable for power plant boilers or HRSGs (heat recovery steam generators), which are often several stories high with intricate tubing inside. With a little help from a fan to create a suctioning draft at the other end of the HRSG, Boiler Dragon™ is able to diffuse through the system for comprehensive protection.

A Protective Molecular Layer

Once the HRSG or boiler is closed, the Vapor phase Corrosion Inhibitors are trapped inside, forming a protective molecular layer on metal surfaces to which they are naturally attracted. This hydrophobic barrier hinders moisture and other corrosive elements from directly interacting with metal surfaces, thus reducing the chance of a corrosion cell forming. For long-term layup, a corrosion coupon can be placed inside the boiler or HRSG and inspected every six months. However, there is no need to reapply Boiler Dragon™ after briefly opening the HRSG. If the protective molecular layer is disturbed during inspection, it will replenish itself from the Boiler Dragon™ vapors still inside the system after reclosure.

Advantages of Boiler Dragon™

Boiler Dragon™ has many advantages in terms of ease of use, budgeting, safety, and effectiveness. No special pressurization or dehumidification equipment is necessary, and Boiler Dragon™ typically does not need to be removed upon recommissioning. Boiler Dragon™ can be applied at a small fraction of the cost of nitrogen blanketing, which can quickly reach tens of thousands of dollars and must be done all over again if the seal is broken. Furthermore, Boiler Dragon™ avoids the dangers associated with nitrogen exposure. Boiler Dragon™ also outpaces dehumidification systems because it does not require a source of power and offers active corrosion inhibition even in the presence of corrosives. Most importantly, power plant personnel have found the effects of Boiler Dragon™ highly satisfactory.

Make Friends with the Boiler Dragon™

HRSG and boiler layup is a fact of power plant life, but it can be far less costly than some facilities make it. Learning how to fight corrosion with the Boiler Dragon™ is a cost-saving strategy for any power plant that needs an effective, worker-friendly means of asset preservation. Contact Cortec® to get specifics on boiler or HRSG layup with the Boiler Dragon™!

Keywords: power plant rust prevention, Boiler Dragon, Vapor phase corrosion inhibitors, alternatives to nitrogen purge, HRSG layup, HRSG corrosion, boiler corrosion, Cortec, boiler layup, corrosion inhibitors

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.