Rust Prevention in Manufacturing: Simple Tips to Protect Parts and Help Your Team Work Smarter

September 9, 2025

The shop floor and assembly line can be vulnerable places for in-process metal goods. Freshly machined metal is a magnet for flash corrosion—when going in and out of air-conditioned QC areas or enduring hot, humid days in parts of the shop that are not climate controlled. Often, workers apply rust preventatives to unfinished parts for interim protection . . . only to remove oils and greases with a harsh chemical cleaner before the next stage of finishing is done. Cortec® encourages manufacturers to eliminate this waste of time and materials by getting creative with VpCI® packaging solutions.

VpCI® Packaging for Quick, Clean Rust Prevention

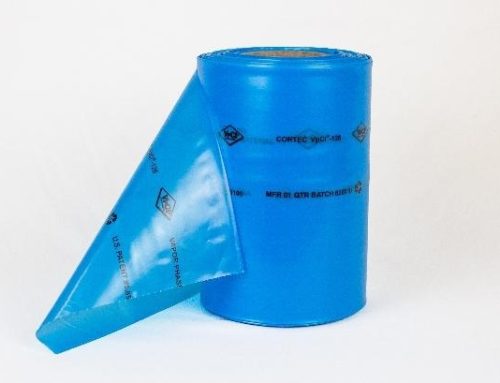

The key advantage of VpCI® packaging is that it is fast and easy to use with little mess—unlike the hassle and cleanup associated with greasy rust preventatives. It is also highly effective. VpCI® packaging comes in many shapes and sizes, all based on Vapor phase Corrosion Inhibitor chemistry, which only requires an enclosed space and a bare metal surface in order to be effective. Vapor phase corrosion Inhibitors emit out of their foundational VpCI® packaging material, diffuse throughout an enclosure, and adsorb (i.e., lightly adhere) on the metal, creating a protective molecular barrier that blocks corrosive reactions with moisture, oxygen, chlorides, or other harsh elements. When the enclosure is opened, VpCI® molecules begin to float away, typically requiring no further cleaning before the component can be used.

Get Creative: Mix-and-Match Packaging for Rust Defense

VpCI® packaging comes in many forms, allowing manufacturers to create a tailored solution that best fits their corrosion protection needs. These materials include VpCI®-126 film and bags in many styles, CorShield® VpCI®-146 paper, and VpCI® emitting materials such as BioPad® and CorPak® 8-MUL Pouches. Some examples of how parts can be protected between manufacturing stages are as follows:

- Line a production bin with a VpCI®-126 gusseted bag, fill with machined parts, and close the bag after each addition. Add a BioPad® if extra protection is needed.

- Sandwich layers of brake disks or flywheels between pieces of CorShield® VpCI®-146 Paper inside a bin.

- Cover racks/carts of gears with CorrCap™ VpCI® Protective Covers (customized shower-cap style versions of VpCI®-126 for easy removal and reapplication) and add BioPad® as an extra source of corrosion inhibitors.

Similar materials can be used for easy protection during shipment

Increase Throughput + Make Life Easier for Assembly Line Workers!

Corrosion is a constant threat, but manufacturers have the privilege of choosing their weapons. Creative packaging with VpCI® materials makes in-process corrosion protection much easier and quicker than using traditional rust preventatives by eliminating oils, greases, and the hassle of cleanup with harsh chemicals. Do you have a spot in your manufacturing process that could benefit from dry, easy to remove corrosion protection to improve your cycle time? Contact Cortec® to help your team develop a creative rust preventative packaging solution for your in-process goods.

Keywords: what is the most effective method of preventing rusting, how to prevent rust on machined parts, how to stop rust from forming on metal, what is the best thing to prevent rust, Cortec, VpCI, VCI paper, VCI film, rust prevention for metal, how to improve cycle time

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.

Related Articles

- FEATURED IN: Corrosion Protection in Manufacturing Featured in ISMR Magazine

- FEATURED IN: Cortec® Successfully Protects Parts from Corrosion and Boosts Manufacturing Efficiency Featured in IPCM Magazine

- FEATURED IN: Simple Tips to Protect Parts and Help Your Team Work Smarter Featured in Fine Engineering Magazine

- FEATURED IN: Manufacturing Corrosion Control: Streamlined Strategies to Safeguard Components and Boost Operational Efficiency Featured in Gazete Makina