Why Choose a Moisture Cure Urethane Like VpCI®-396?

December 24, 2020

systems—from high performance water-based acrylic (e.g., VpCI®-386), to water-based epoxy (VpCI®-395), to solvent-based moisture cure urethane (VpCI®-396) coatings. Each coatings system has its own advantages for different applications. So, why would someone want to use a moisture cure urethane like VpCI®-396, for instance? There are several reasons.

systems—from high performance water-based acrylic (e.g., VpCI®-386), to water-based epoxy (VpCI®-395), to solvent-based moisture cure urethane (VpCI®-396) coatings. Each coatings system has its own advantages for different applications. So, why would someone want to use a moisture cure urethane like VpCI®-396, for instance? There are several reasons.

1. Because moisture cure urethanes can cure in the presence of moisture, they are a good choice for tropical environments or chemical processing facilities with lots of moisture in the air.

2. They offer good durability for harsh environments. “Moisture cure urethanes have excellent adhesion to most substrates,” noted Technical Service Manager and former Coatings Chemist, Rick Shannon. “They are chemical resistant and have very good corrosion resistance when properly formulated.”

3. VpCI®-396 in particular is easy to use because it is a one-component primer that does not require extra mixing of two components and therefore does not have pot life issues.

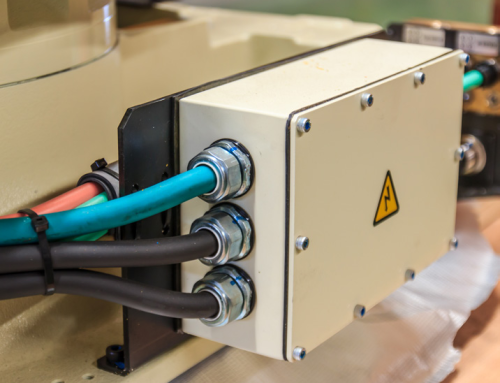

VpCI®-396 moisture cure urethane is usually recommended for use in harsh conditions as a primer with a topcoat of VpCI®-384 for greatest durability. A key example of this system was its use on powerline clamps at a wind farm substation in Brazil exposed to blowing sand near the ocean. VpCI®-396 Aluminum has also been used as a topcoat over CorrVerter® Rust Converter Primer on 200 rusty railway electrical piers in Serbia. Another potential use of VpCI®-396 Aluminum is as a topcoat over VpCI®-395 Water-Based Epoxy Primer in a chemical plant where durability to fumes and liquids is needed.

There are many applications where VpCI®-396 is an ideal choice. Contact Cortec® for further support if you think your application may be a good candidate for a VpCI®-396 Micro-Corrosion Inhibiting Coatings™ system: https://www.corteccoatings.com/contact-us-2/

For a PDF version please click here.